We all know that pharmaceutical packaging is a complex process. Going from a tablet to a boxed product on the shelf or a box in transit involves many tedious steps. Of course, the premise of this is that you have never used a blister line.

Traditional pharmaceutical packaging is usually completed by multiple machines through multiple steps, and each machine is responsible for one of the packaging steps. However, the blister line has changed that. Compared with the traditional multi-machine collaborative packaging mode, the blister line has the following advantages:

1. High degree of automation

The blister line can realize automatic control of the entire packaging process, and all operations only need to be set and adjusted on the control panel, which can save a lot of labor costs and time costs for enterprises.

2. High productivity

Each process of the blister line does not require manual cooperation, and multiple packaging steps can be carried out in a coherent and orderly manner. It greatly improves the production efficiency of product packaging, which also means that enterprises will obtain higher economic benefits.

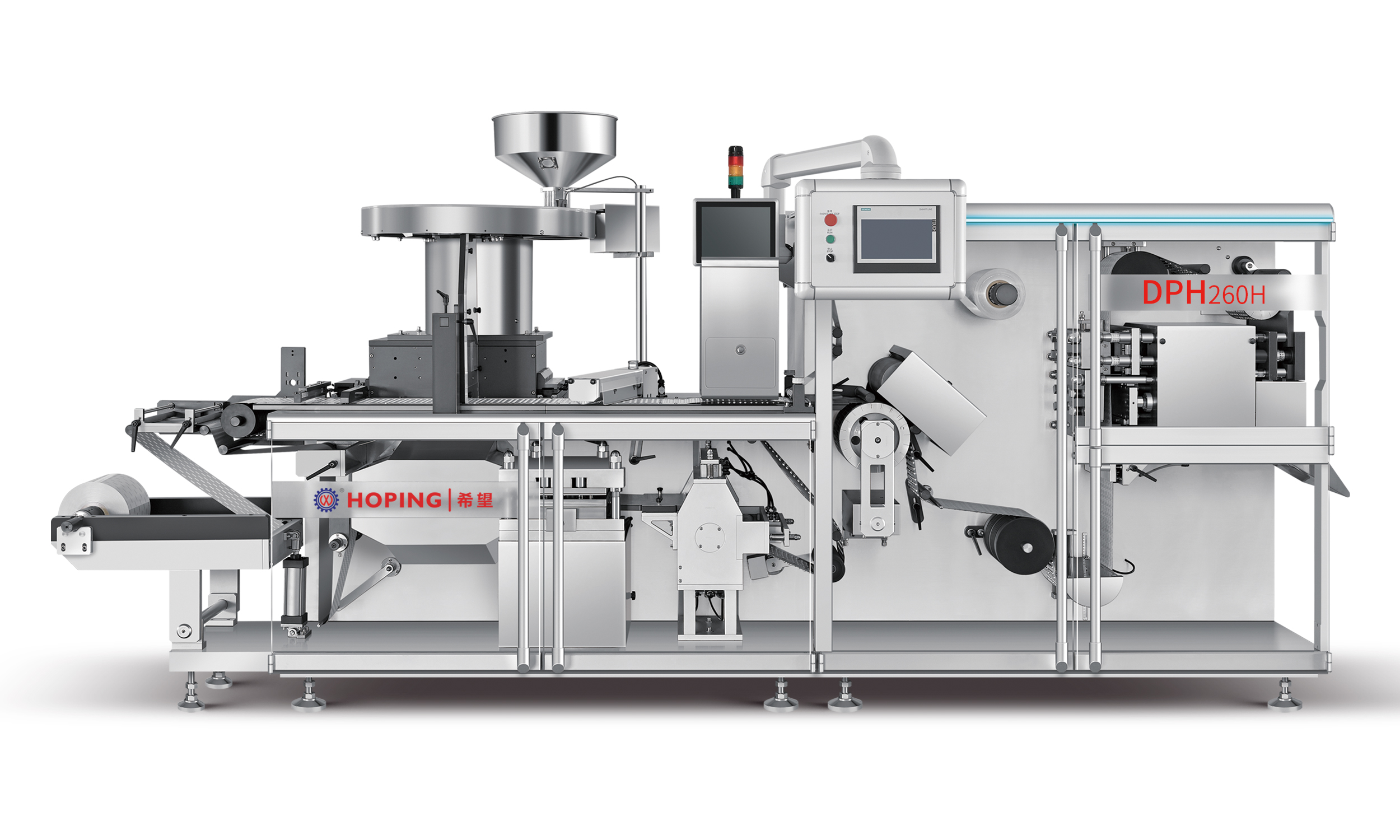

3. All in one

The blister line integrates functions such as blister, flow packing, cartoner, etc., saving users the trouble of purchasing multiple types of machines. Compared with using multiple machines for packaging separately, the blister line obviously has higher efficiency and a more convenient user experience.

The IXW800 subverts the traditional conveyor belt connection mode, instead uses a variety of transfer devices to connect the components, and is equipped with a precise and controllable intelligent full servo system, which greatly improves the stability of the drug packaging process. With the development of 2-D3 top-loading robot technology, PVC/aluminum foil/pillow wrapping material automatic connection technology, 2-XTS12 directional rotating manipulator transfer system, ultra-high-speed double-track sleeper wrapping system, intelligent packaging linkage production management system, and other technologies, IXW800 has made the production line non-stop production reality, and the new dual-track synchronous production mode has brought the production capacity of pharmaceutical packaging to a new level.

The IXW800 can complete multiple processes such as blister packaging, flow packing and boxing at one time, which enables consumers to have a more convenient and fast experience. If you choose to connect the matching end-of-line packaging machines like the XWK4060 strapping machine and ICP12 unpacking, sealing and palletizing machine, you will truly get a complete production line from preliminary packaging to final packaging. In addition, the blister output of IXW800 can reach up to 800 blisters/min, and the carton output can reach up to 500 cartons/min. Compared with other manufacturers’ blister-cartoner lines, it has obvious speed advantages. All in all, the IXW800 will save you a lot of time and costs, and greatly improve the production efficiency of end users.

We warmly welcome all kinds of pharmaceutical manufacturers to come to order. And we sincerely invite you to enjoy the convenient experience with Hoping machinery!