No. 88, Weiwu Road, High-tech Industrial Park, Ruian, Wenzhou, Zhejiang Province

Tel: 86-577-65579899

WhatsApp: +86 13356105292

E-Mail: info@hoping.email

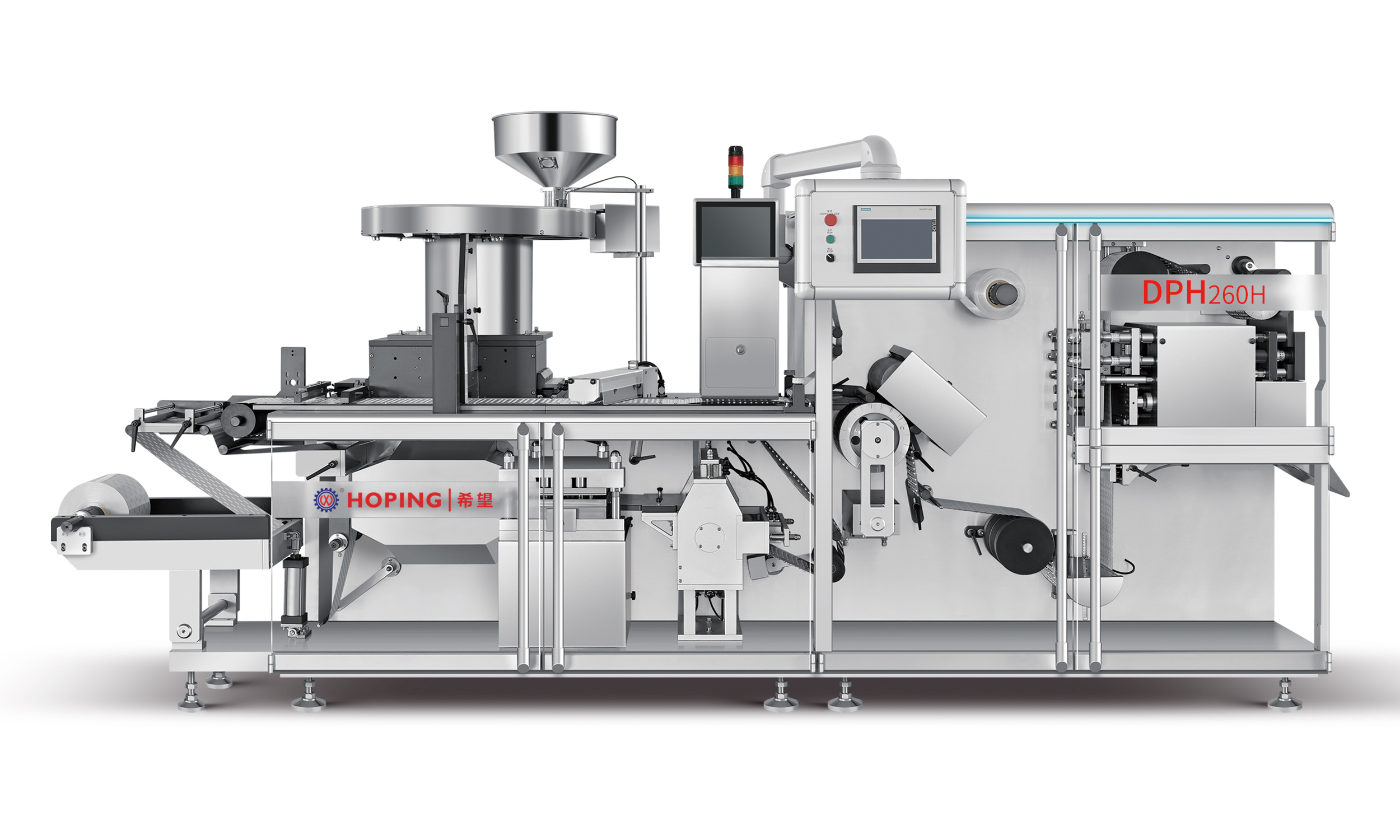

Blister Machine DPH260H

DPH260H Intelligent High Speed Roller-Plate AL/PL and AL/AL Blister Machine

Product Description

Blister machine DPH260H is a blister packaging machine in the continuous drum sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

The DPH260H is a new generation product developed by our company to meet the high productivity needs of our customers. Its punching times can be 200 times per minute, which is about four times higher than ordinary blister machines.

This high-speed blister machine is equipped with special feeder for shaped pills and edgeless punching, which greatly improves the production efficiency. This high-speed blister machine also has the characteristics of high punching frequency, low energy consumption, accurate and stable action and easy mold change.

Product Features

- Max capacity 600 blisters/min[i]

- Continuous roller sealing

- Different feeding methods depend on customer needs

- PLC control system and Siemens smart 1000 (10 inches) HMI screen

- Double servo drawing, stable and accurate operation

- Convenient mold change

- Splice station, convenient material change

- Stagger blister unstriped waste cutting (save waste material)

- Design in line with GMP requirements

[i] Production according to the standard plate size 80*57mm*mm

Product Description

- Continuous Roller Sealing. The contact area during heat sealing is small and the heat time is short, making the heat sealing more thorough and further increasing the speed of the whole blister machine.

- Punching station is controlled by servo motor, which synchronizes the blister. And the blister change just needs to shift the position, no need to change the gear. Edgeless punching makes the longitudinal waste edge become 1mm, with no transverse waste edge.

- The oil pump automatically refuels every 10 minutes (also can be set separately) to play a role in lubrication and cooling, protecting the smooth operation of the blister machine and extending the service life of the blister machine.

- This blister machine is equipped with a packing film splicing platform device, which makes splicing film smooth and easy.

- All parts in contact with medicine are made of stainless steel and non-toxic materials and are meeting “GMP” requirements.

- The production line with EMERGENCY STOP device, electronic counting, batch number, punching, automatic stopping and alarming if the film is used up or broken, etc. And has a smooth process and intuitive production process.

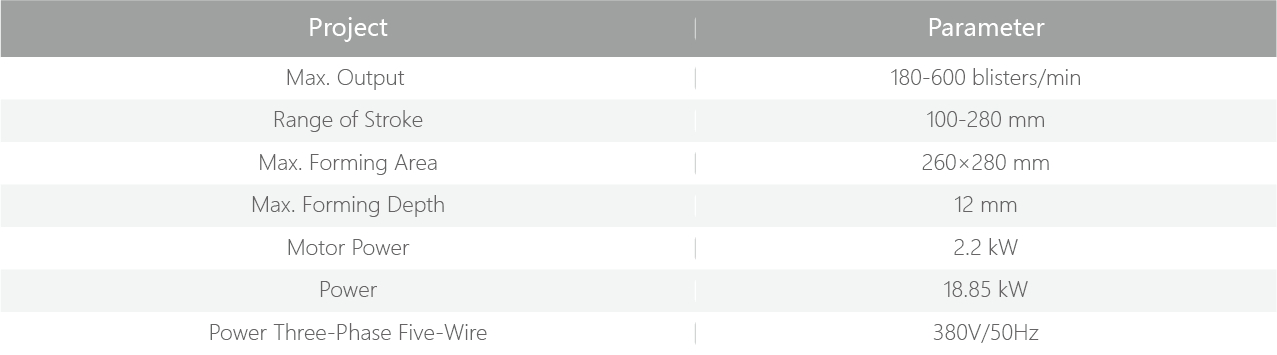

Technical Data

*The above parameters are for reference only, please contact sales for actual parameters.

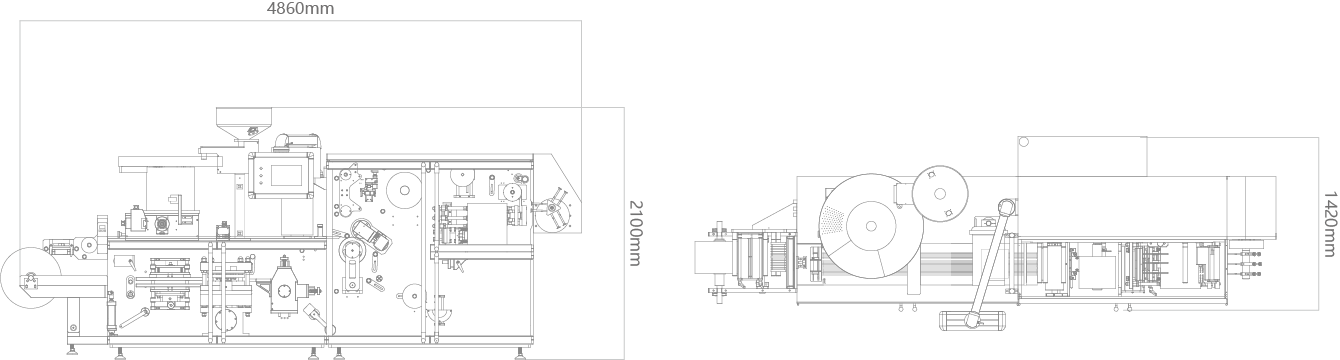

Dimension

Related Products