No. 88, Weiwu Road, High-tech Industrial Park, Ruian, Wenzhou, Zhejiang Province

Tel: 86-577-65579899

WhatsApp: +86 13356105292

E-Mail: info@hoping.email

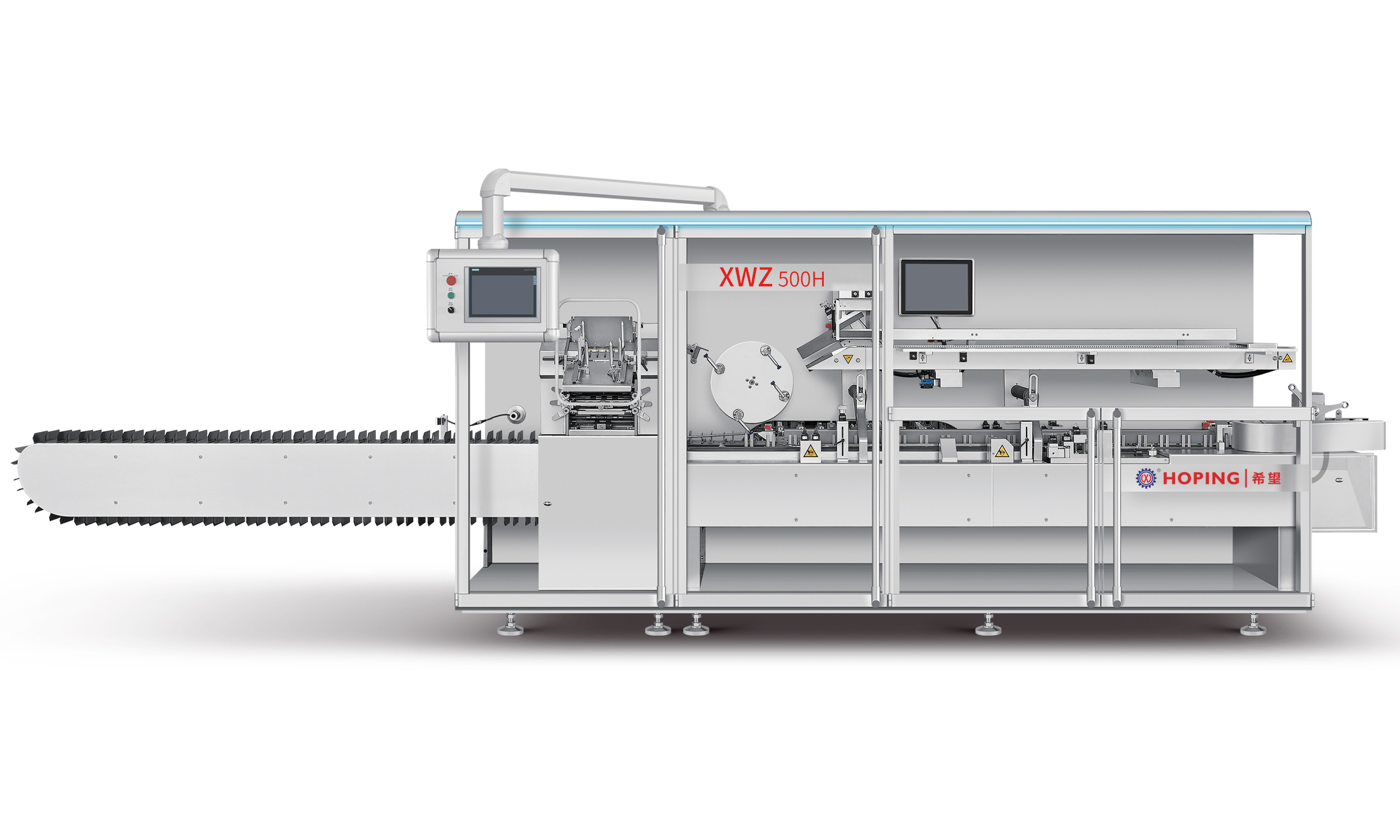

Cartoner XWZ500H

XWZ500H Full Servo High Speed Cartoner

Product Description

Cartoner XWZ500H is a continuous type of intelligent high-speed cartoning machine with full servo and is also suitable for food packaging, cosmetic packaging, and packaging in related industries.

This cartoner is suitable for food packaging, chemical packaging and packaging of related industries, with a wide range of use, short mold adjustment time, easy assembly and debugging. And according to the different requirements of users, the products can be changed regularly. This cartoner is suitable for the production of single variety in large quantity, and can also meet the production of multiple varieties in small quantity. The discharge port of the cartoner can be matched with various types of banding machines.

Product Features

- Maximum capacity 500 cartons/min

- Continuous multi-pusher feeding

- Motion controller and Siemens TP900 (9 inches) HMI screen

- 10 axes full servo fully synchronized operation control

- Four-head vacuum suction and discharge box

- Quick size adjustment without replacement

- Steel coding, optional coding machine

- GMP compliant design

Product Description

The cover of this cartoner is made of high-quality 304 stainless steel and aluminum alloy tempered glass protective door. The aluminum alloy tempered glass protective door has built-in Schneider door magnetic switch (CE-certified). If the protective door is opened during the production process, the machine will automatically stop working to ensure the safety of the operators.

The whole cartoner adopts continuous cartoning, and the cartoner is in smooth running condition for cartoning, and the noise and load of mechanical operation are minimized.

The system adopts Siemens Simotion Motion Control System to realize 10 stations full servo fully synchronous operation control, which makes the operation of the debugging and adjustment in the HMI. The operation can be more humanized.

The program adopts Siemens Simotion Motion Control System for the whole process of automatic monitoring to ensure 100% qualified finished product output at the discharge port. And automatic counting is displayed on the screen.

This cartoner adopts a number of highly reliable mechanical overload automatic protection devices, so that the cartoner can protect itself from damage in the event of an unexpected situation during operation.

No need to change parts when changing products. Products can be directly converted through the adjustment mechanism, each adjustment part uses the grip to adjust the set screw for fastening, easy to operate.

All parts in contact with drugs are made of stainless steel and non-toxic materials, in compliance with “GMP” requirements.

Security:

If there is no carton, the blister will not enter the carton, and the whole machine will automatically stop and sound the alarm.

If there is no manual, the blister will not enter the carton and the empty carton will be rejected. The whole machine will stop automatically and sound the alarm.

If there is no blister board, the carton and manual will be waiting. The whole machine will stop automatically and sound the alarm.

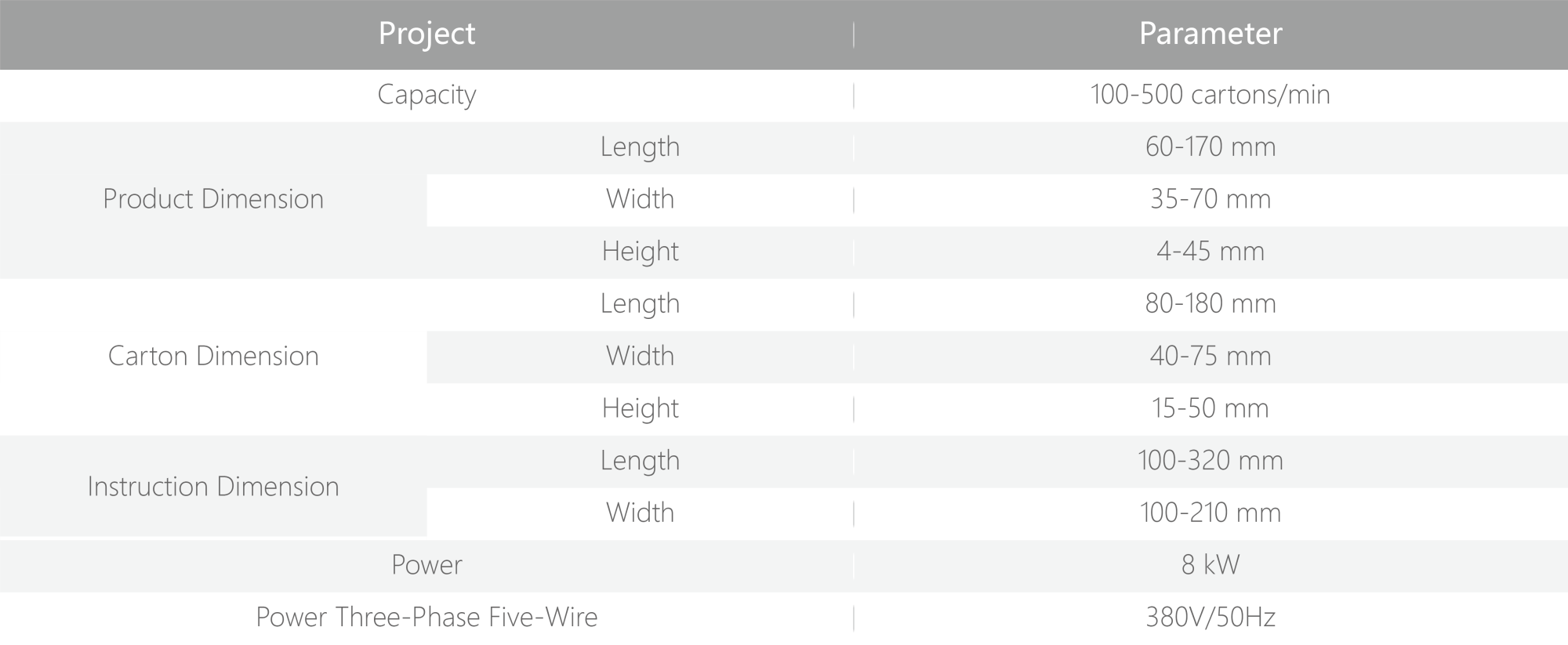

Technical Data

*The above parameters are for reference only, please contact sales for actual parameters.

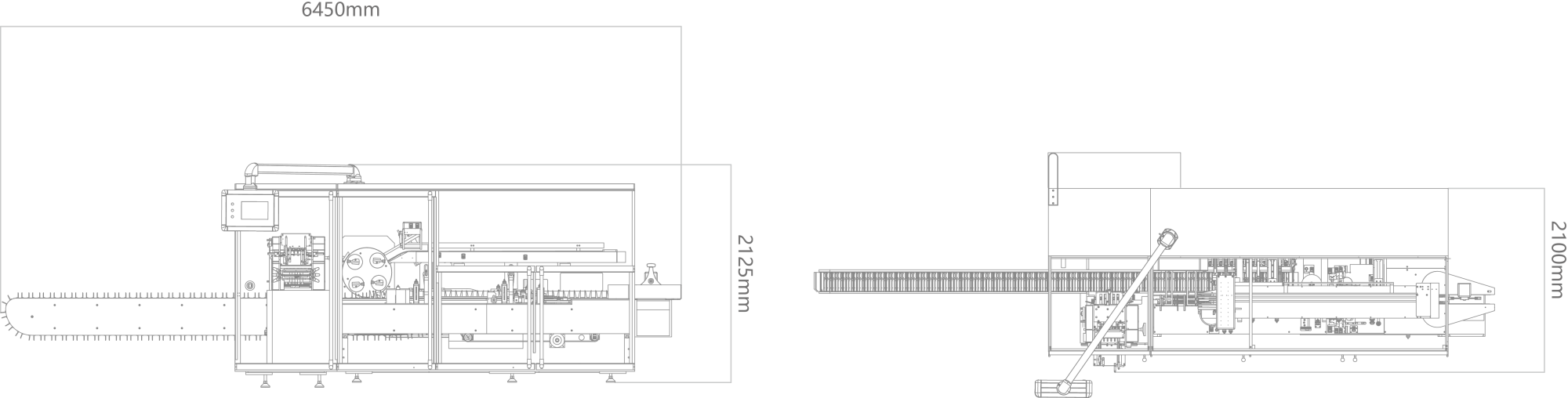

Dimension

Related Products