No. 88, Weiwu Road, High-tech Industrial Park, Ruian, Wenzhou, Zhejiang Province

Tel: 86-577-65579899

WhatsApp: +86 13695839656

E-Mail: chris@hoping.email

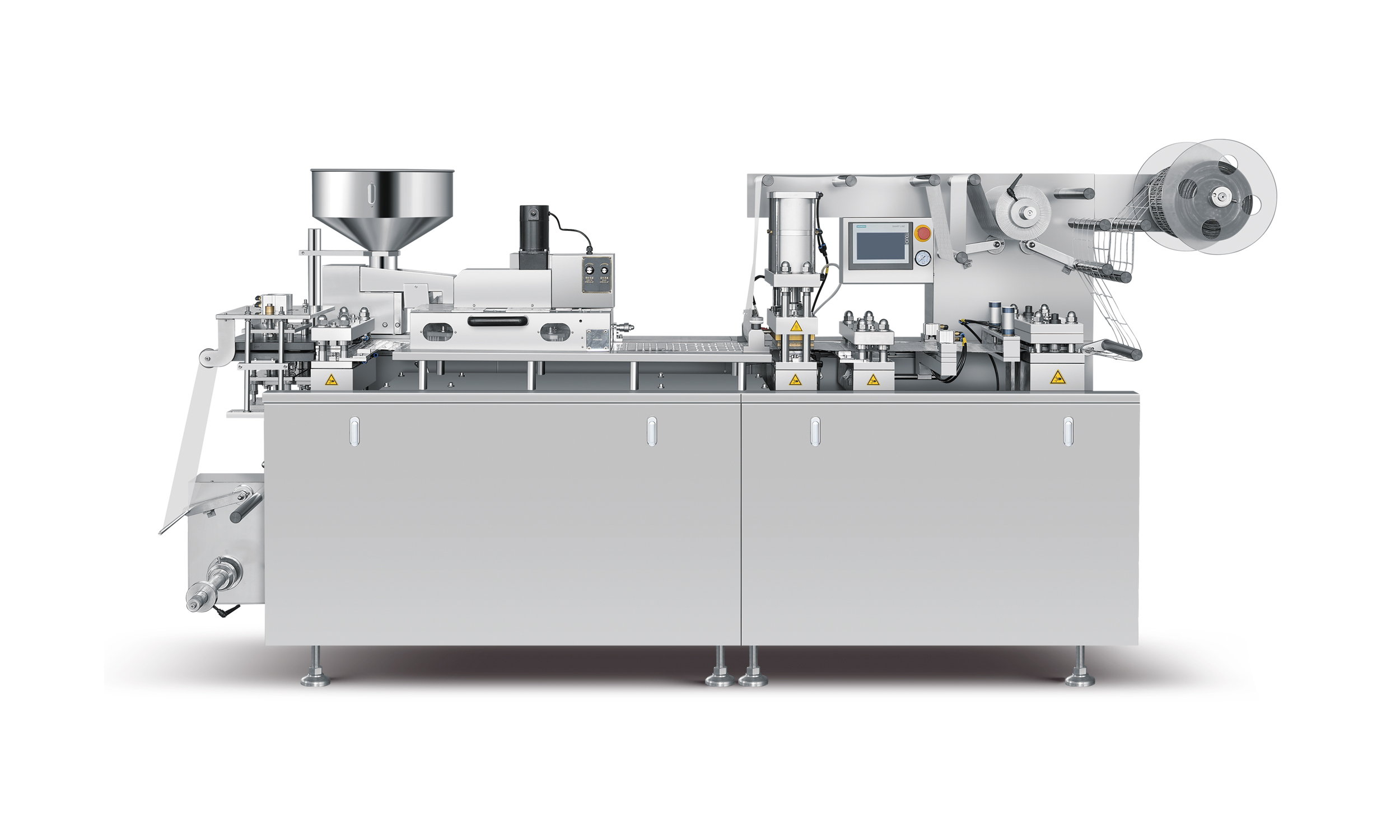

Blister Machine DPP250F I

DPP250F I Intelligent Plate AL/PL and AL/AL Blister Machine

Product Description

DPP250FI is a blister machine in intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

The blister machine is a special equipment for blister type aluminum/plastic, aluminum/aluminum (PTP) composite sealing packaging of pharmaceuticals (tablets, capsules, ampoules) food, medical devices and similar materials, which adopts positive pressure forming and flat pressure heat sealing, so it has the characteristics of the stiff and flat blister, and is popular among industry professionals.

Product Features

- Max capacity 200 blisters/min[i]

- Intermittent plate sealing

- Different feeding methods depend on customer needs

- PLC control system and Siemens smart 700 (7 inches) HMI screen

- Mechanical drawing, stable operation, adjustable stroke (optional servo drawing)

- Convenient mold change

- Scrap material collection

- Design in line with GMP requirements

[i] Production according to the standard plate size 80*57mm*mm

Product Description

· The molds of the blister machine are positioned by keyway and fixed by pressing plate. Don’t need to adjust the parallelism and left/right movement when installing the forming mold and heat-sealing mold, so it is more convenient to change the mold

· The punching station of this blister machine is designed to punch horizontally, which can reduce the waste edge from punching.

· This blister machine adopts variable frequency speed control: (its punching speed can be available from 20 to 50 times/min) to set the corresponding punching times according to the length of stroke and the difficulty of filling materials, etc.

· The stroke of the blister machine is adjustable. And the servo traction device is optional.

· This blister machine adopts compressing pair heating-plates, which shortens the heating length of the plastic film and reduces the heating power and temperature, thus enhancing the stability of the plastic film.

· Upper and lower mesh plates (concave and convex) cooperate for heat sealing (also can be line seal), due to equal stress, the curling phenomenon of blisters is avoided, meanwhile the sealing performance is improved.

· All parts in contact with medicine are made of stainless steel and non-toxic materials and are meeting “GMP” requirements.

· The production line with EMERGENCY STOP device, electronic counting, batch number, punching, automatic stopping and alarming if the film is used up or broken, etc. And has a smooth process and intuitive production process.

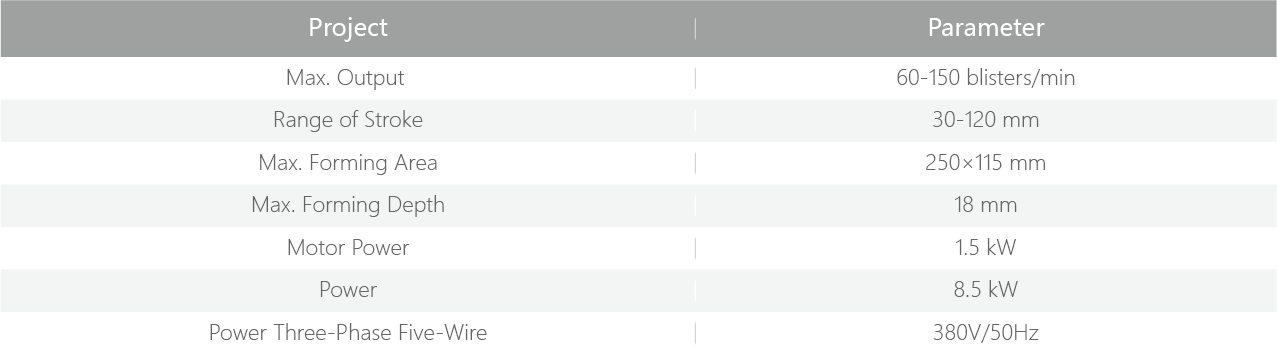

Technical Data

*The above parameters are for reference only, please contact sales for actual parameters.

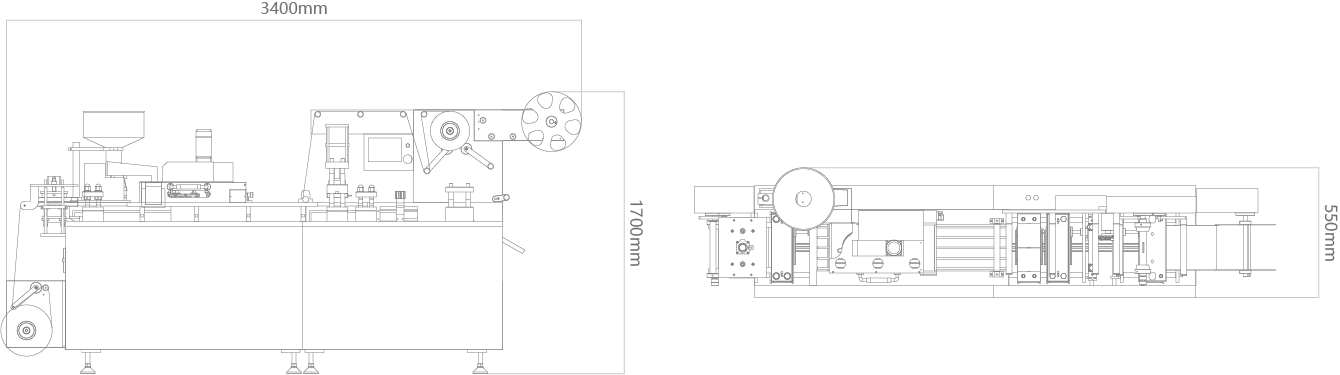

Dimension

Related Products